How to Test & Fix the Printed Circuit Board (PCB) Defects?

Diagnosing of Defective Printed Circuit Boards (PCB)

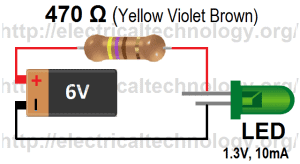

Before getting into details of printed circuit board (PCB), there are some basics you need to know about circuits.

Electricity: It is the power provided to every instrument ranging from small lights to heavy machinery. Electricity is just a flow of electron from one level to other (upper level to lower mostly).

Voltage, current, resistors, capacitors and inductors are considered as primary elements of any electrical scenario called circuit. Electrical current can be in two forms either a sinusoid AC (alternating) current or simply a straight line called direct or DC current.

In hardware development of electrical circuit, to get all the components of circuit on one single place or board is called PCB designing.

Printed Circuit Board (PCB) is the common name that is used for these electrical boards. In history, PCBs were been developed by going through a complicated procedure of point-to-point wiring and these circuits were highly exposed to get failure or damage. After those more accurate design techniques were developed which were more secure.

These days composition of printed circuit board consists of four major components.

- Silkscreen

- Solder Mask

- Copper

- Substrate that is fine fiberglass

Older PCBs were single layered but these days multi layer PCBs are present and used in the market .PCBs are multi layered because these days complexity of electrical circuit is also increased.

Newly developed PCBs have high pitch parts in which most of the parts are unidentified, on testable and more they involve complex troubleshooting and repairing techniques. Older circuit boards were able to be repaired by using automatic test equipment but these days it is not possible. Techniques used for troubleshooting were

PCB Troubleshooting Techniques

- Checking of solder joints

- Tracking of problems

- Troubleshooting of discrete elements

- Checking of integrated circuits (ICs)

- By using software help

- Visual Inspection

- Functionality test

Most of these techniques become non functional when they need to cope with modern circuit boards.

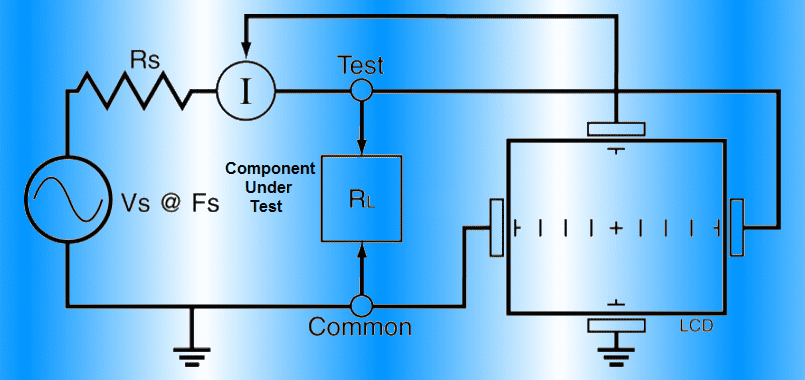

A newly developed VI signature analysis technique which is best for troubleshooting of completed circuit elements

Analogue Signature Analysis to Test the Unpowered Printed Circuit Boards (PCBs)

One of the best essential device that is used for detailed analysis of faulty components in a circuit. It is one of the best choices to test PCB when component signatures or documentation has been lost. This test require no power supply so it is best when we want to check faulty or dead boards as it is not safe to power them up.

- You may Also read: What is Arduino and How to Program it?

A sine wave is provided to particular component under test using two probes. Resulting currents, voltages and shifts in phase are displayed on LCD. Current is on y axis while voltage is on x-axis and resultant trace is displayed as signature on screen. To use this device you need to have solid theoretical knowledge of signatures of different components and its complete understanding is required.

Strategy to diagnose a faulty PCB

There are three different stages of this technique.

- Detection of fault using VI instrument. Unidentified high pin count is tested by alternating voltage.

- Second stage is to detect location of the faults. It deals with minute analysis to pinpoint the faulty component. But not like functionality test it performs tests only on input and output stages.

- In third stage new functional components are placed in circuit after removing the faulty components

Analysis/Results

In an electrical circuit all the components are either in series, parallel or a mixed combination (Series-Parallel) both so it become impossible to identify their signatures so the only suitable solution in this scenario is to take a new PCB and compare the signatures of defective one with the signatures of functional one.

- You may also read: Design & Simulation Tools for Electrical/Electronics Engineers

To compare the signatures, first thing is to take all signatures of defective PCB new functional PCB if available other you must have saved signatures of components. But if you have a fully functional PCB take all its signatures by using multimeter .Voltage resistance current and inductance of every component is computed and then is compared with all the signatures of defective PCB (Printed Circuit Board).

- First of all refresh all the points (remove dry or damaged solder if any) and compare signature if signature matches fault has been removed otherwise go to next step.

- In this step tracking is performed as there are many tracks in a PCB so there are a lot of chances for tracks to get damaged, if any track is damaged jumper wire can be used to repair tracks.

- This is the last step in which functionality test is performed on every pin of linear integrated circuits, input and output on every pin of IC is checked if it matched with the original data sheet it is fine otherwise you have to remove that IC.

Also Read:

- How to Program PIC18 Microcontroller in C. Step by Step

- How to test a battery with Test meter?

- What is Motor Efficiency & How to improve it?

Reference : Analog Signature Analysis, Saelig Co. Inc.

It is extremely difficult to know if a circuit board needs repair unless you are a professional and know what to look for. I think this little trick that you mention is going to help people figure out if their circuit board needs repair. While I was reading on http://www.contecdirect.com/services.php I read a list of electronics that use circuit boards to operate. I was surprised to see things like alarms and fire suppression systems on there.

PCBs are very simple to troubleshoot for an experienced one, as there is not much equipment you will need in order to troubleshoot your average printed circuit board repair. The most versatile tool used for troubleshooting PCBs is a multimeter. In cases, when deep troubleshooting is required for PCB repair then we need complex technology to properly troubleshoot a PCB and trace a problem back to its source, like you may need to use something like an LCR meter, an oscilloscope, or a power supply and logic analyzer.

i like it so much for very good explanation with image